Non-destructive testings - NDT

Multitest Ltd. performs large range of non-destrucive examination tests:

- Radiographic inspection

- conventional RT

- computer radiography - CR

- digital direct radiography - DDR

- radiography method for thickness measurement - Ultrasonic testing

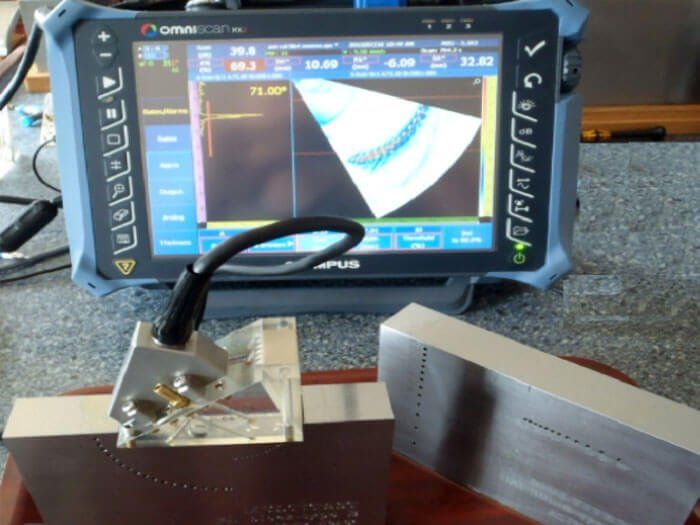

- conventional UT

- phased array UT (PAUT)

- TOFD of welded joints

- Thickness measurement by TOFD method

- mechanized ultrasonic method by zonal discrimination technique AUT

- Ultrasonic thickness measurement (UT-TH) - Visual inspection VT

- Magnetic particle inspection MPI

- Dye penetrant inspection DPI

- Eddy curent inspection ET

- surface and subsurface imperfections inspection

- coating thickness method

- material sorting and type of metal products - Heat exchangers and air conditioner (chiller or evaporator0 inspection:

- methods:

‣ ECT (eddy current)

‣ RFT (remote field)

‣ NFT (near field testing)

- material:

‣ Ferromagnetic (carbon steels, nickel)

‣ Mildly ferromagnetic (monel, 400 series stainless steel, Duplex stainless steel)

‣ No-ferromagnetic (copper, brass, aluminium, titanium, 300 series stainless steel, Inconel and others) - Macroscopic inspection

- Hydrostatic/ hydraulic inspection method

- Pneumatic tests

- Leak test LT

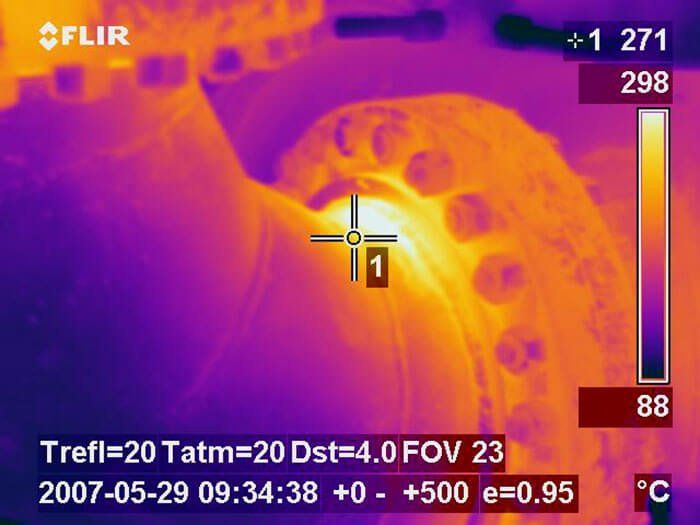

- Termovision inspection ТТ

- Acoustic emission inspection АЕ

- Holiday detection test

- Corrosion inspection (pitting)

- Crack depth measurement

- Geometry dimension measurement and calibration of pipeline and gas pipeline

- Weight measurement

- Cyclic pressure method

- Inspection of static and dynamic damage- FFS (Fitness-For Service), Residual Life Assessment

- Ferrite content

- Roughness inspection

- Moisture inspection

- Illumination inspection

- Melt flow (MFR) or Volume (MVR) index of polymers

- Insulation resistance inspection

- Spectral analysis and PMI

The non-detsructive examination activities shall be carried out in an accredited testing laboratory in accordance with BDS EN ISO/IEC 17025:2018 and accredited inspection body in accordance with BDS EN ISO/IEC 17020:2012.